Brilliantly clean Sanitary Ware - as if by magic!

Ceramic sanitary ware with our special coating are child´s play to keep permanently sparklingly clean. Because lime scale, fat and dirt cannot get a firm grip. Germs are destroyed, unpleasant odours and fungi are avoided. At the same time, our special coating is totally non-toxic and free of irritants. The coating is permanently burnt into the ceramic surface and has a

practically unlimited lifespan. That is why we guarantee the full effect - permanent.

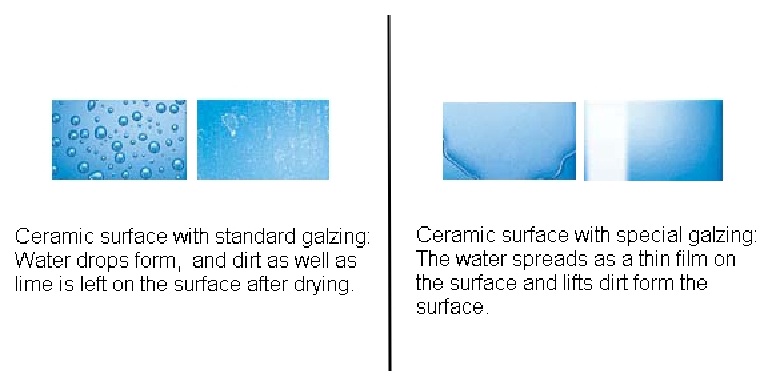

This special coating process makes the ceramic surface hydrophilic. Instead of forming drops, water is distributed as an extremely thin film over the surface area. The decisive advantage: soiling is simply rinsed off and can be wiped away in no time at all. Harmful germs which often lead to unpleasant odours, are oxidized and destroyed in a natural way. Conclusion: brilliant cleanliness, freshness and hygiene – permanent and without effort.

Effective against bacteria: our products are predestined for use in areas where hygiene is of the important. The surface coating decomposes bacteria, fungi and germs and prevents the evelopment of new pathogenes.

Effective against dirt: In addition and thanks to our special coating process, the ceramic surface can be kept clean without great effort. This permits to reduce the use of cleaning agents and thus their costs considerably, and to protect the environment. Thereby reducing the use of cleaning agents to lower maintenance costs and help preserve the environment.

Effective against odours: the special surface treatment eliminates unwelcome odours quickly and thoroughly. This effect is already guaranteed at a normal level of indoor lighting. There are no health risks and secondary effects: according to international tests and analyses, the coating is absolutely non-toxic and free of irritating substances.

Even normal room lighting is sufficient in order to activate the catalyst, titanium dioxide (TiO2), that is contained in the coating. The consequence: the surface tension of water that is to be found on the ceramic surface is reduced and, as a thin film it even rises off stubborn dirt like lime scale and grease. At the same time, the photo catalytic reaction leads to the activation of oxygen in the atmosphere. As a result, bacteria are destroyed and renewed growth reliably prevented.

Modern bathrooms are oases of relaxation. Our “almanit” ceramic sanitary ware with it’s special coating make an essential contribution to the feeling of well-being. Because they permit the realization of individual design concepts and are clean again in the twinkling of an eye.

Our unique coating is burnt into the ceramic surface. As a result, it is absolutely indestructible – for the entire life of a product. We assure permanent effortless cleaning and hygienic effectiveness with its long-term guarantee.

The surface is an integrated part of the ceramic manufacturing process. The coating material (Titanium Dioxide) is applied during the glazing and subsequently baked onto the surface of the tile. The photo catalytic reaction is permanent and is activated by a normal level of indoor lighting.

No potentially harmful materials are used – Titanium Dioxide (TiO2) is contained in many household products such as lipsticks and toothpaste.

“almanit” cistern fittings are specially designed to assure maximum water saving. They are tested and approved as “low consumption units” in accordance with DIN 1358-6 standard. Our toilets use a maximum of 6 litres per flush. This means that a 4 to 5 person household can save up to 27.000 litres per year (compared with conventional 9 litre cisterns).

All cistern fittings are supplied with a dual flushing button; the smaller button flushes 3 litres and the larger one flushes 6 litres. This helps to even reach a higher water saving per year.

Our „almanit sanitary ware“ products are manufactured in accordance with European EN standards which specifies the sizes, dimensional tolerances, mechanical, physical and chemical requirements, surface quality requirements and marking of ceramic parts.

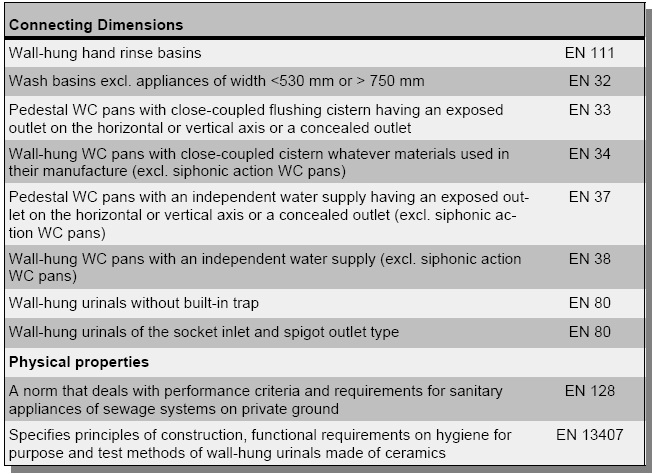

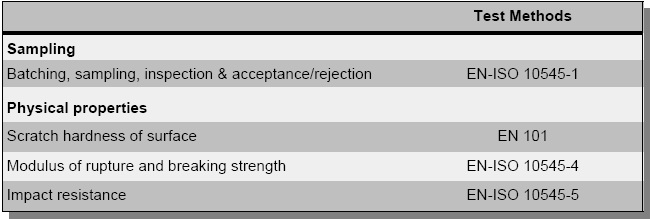

The most important European standards for testing ceramic parts are:

Other European standards for testing ceramics are: